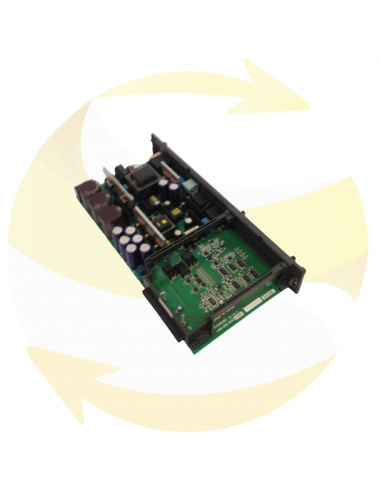

A16B-2203-0370 - Power Supply Unit - FANUC

This FANUC power supply board is part number A16B-2203-0370. It is installed on FANUC RJ3 Robot.

This FANUC card is at your disposal to replace your defective equipment and has a guarantee adapted to your needs.

Card reconditioned and tested on bench manufacturer (Test 100%).

Like the Series 15B, the power source unit of the Series 15i/150i is provided with a power ON/OFF control function. Therefore, basically, the input unit need not be prepared for the power source unit on the Series 15i/150i for power ON/OFF control.

CP1

This is the AC input connector for the control unit. The AC specifications are as follows:

R, S 200 to 240VAC+10% –15%, 1–phase, 50Hz/60Hz±3Hz G Ground (class 3 grounding)

CP2, CP3

These AC outputs are ON/OFF–controlled synchronized with power ON/OFF of the control unit.

The AC output specifications are the same as those for AC input to CP1.

The AC input specifications of CP1 may be limited depending on the AC input specifications of the equipment connected to CP2 and CP3.

When the equipment connected to CP2 is 200/220VAC equipment (not 240VAC equipment, the AC input specifications of CPS becomes 200/220VAC.

The maximum AC output supplied from CP2 and CP3 combined is 2.5A. If capacitance is insufficient.

To prevent deterioration of the control unit due to rush current when the power is turned on, the capacitance of the load connected to CP2 and CP3 must be kept to 440 μF for CP2 and CP3 combined. When an inductive load is connected, insert a spark killer parallel to the load.

CP4

This connector is for control the power source of ON/OFF button connections

Alarm inputs (AL, OFF)

The alarm inputs are for turning the system power off when an alarm signal from outside the control unit is received. Input the signal of the input to close when an alarm state is generated.

(Contact Specifications)

Withstand voltage 30 VDC min. (across contacts) Current 100 mA min. (min. load 1 mA)

Alarm outputs (FA, FB)

FA and FB are short–circuited when the DC output fuse used for the power source unit of the control unit blows, or when overvoltage, overcurrent or other abnormality occurs in the DC output of the power source unit. FA and FB are also short–circuited in the same way by the alarm inputs (AL, OFF) closing. This signals are held until the OFF button is pressed, or the input power source (AC input of power source unit) is cut. When these signals are output, the power source of the control unit is cut, and the function of the power ON button is disabled.

(Contact Rating) 50VDC max. 0.5A max. 50VAC max. 5VA max.

CP5

This is the +24VDC output.

CP5 is used as the power sources for the LCD unit and hard disk unit.

CP6

This is the power source (+24VDC) for the machine interface I/O (e.g. connection unit, operator’s panel connection unit).

2A is the maximum DC output that is supplied from CP6.

FANUC is a Japanese manufacturer of industrial robots, machining centers and numerical controls for machine tools

Since its creation in 1956, when the company’s founder, Dr. Seiuemon Inaba, introduced the concept of digital controls, FANUC has always been at the forefront of manufacturing techniques in the world. Moving from the automation of a single machine in the late 1950s to the automation of entire production lines over the following decades.

.png)